Educating Sommeliers Worldwide.

By Beverage Trade Network

Wine faults are rather prevalent; if you're a wine consumer, you've drunk your fair share of wine with flaws in it without even realizing it. You might have liked the wine more, or you might have dismissed it as a terrible grape. A wine defect occurs when something goes wrong with the grape, the fermentation or manufacturing process, the maturing process, or the storage of the wine after it has been bottled and shipped.

Wine faults could be classified into several groups, such as flaws caused by oxidation or reduction (typically sulfur-related). Some are caused by unwelcome yeast or bacterial development in wine, ambient scents, or packaging taints. It is a broad field of research.

It all sounds very geeky, but trust me when I say it's important to know! Let's get started!

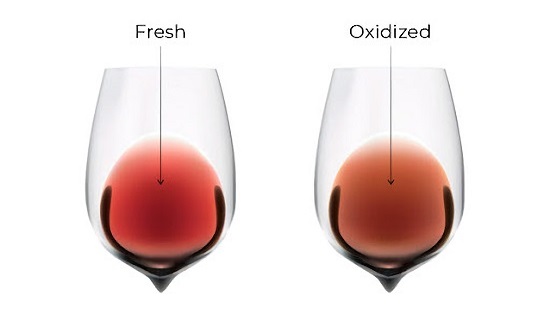

1. Oxidation Faults: The most prevalent flaw is oxidation, which often goes undiscovered. Oxidation occurs when the wine is subjected to excessive degrees of oxidation outside of the planned wine-making process, with unfavorable results.

- This could be due to the air in that half-empty bottle that's been sitting in your kitchen for far too long or insufficient storage conditions, or, more commonly, a faulty seal (cork/screwcap).

- When aromas in a wine break down by oxygen, they lose their distinct varietal character and become stale or lifeless.

- When we swirl and take that first sniff of our wine, the first thing we notice is whether it's fresh and vibrant or has been opened for a while and has gone flat and stale.

Image source: Airtender, Difference between Fresh wine and Oxidized wine

- There are also some visible indicators of oxidation. For example, White wines are far more prone to oxidation than reds, owing to the increased tannin levels in reds acting as a buffer. On the other hand, red wines may develop a faint brickish color or browning. The cause of stale aromas we detect in oxidized wine can be due to aldehyde molecules, which can have a nutty odor or smell like crushed apples.

- You can observe this by opening a new bottle, pouring a glass, and keeping it for roughly a week. Then, drink some and compare it to your first glass.

2. Cork Taint: Cork taint is one of the most unappealing and common organoleptic flaws in wines. It is caused by fragrant chemicals found in cork transmitted into the wine after bottling.

- A musty or moldy aftertaste distinguishes cork taint. A minor level of taint may just cause a change in the aroma or flavor of the wine. Cork is a natural product derived from the cork oak, and its quality is based on appropriate agricultural practices and quality control during production, transit, and storage.

- However, moisture exposure of corks can favor the growth of these organisms, resulting in the production of metabolites with extremely low flavor thresholds that can be leached into the wine and cause strong, harmful taints.

- The chemical responsible for cork taint is 2,4,6-trichloroanisole, but other chloroanisoles and chlorophenols can also contribute to cork taint. In addition, TCA can be found in oak barrels and winery processing lines, causing entire batches to be damaged rather than individual bottles.

- Cork-tainted wines have a musty aroma similar to a wet newspaper or rotting cardboard. These off-flavors dominate the corked wine, because of which the fruit flavor is negligible. Therefore, if your wine has musty, damp, or aged odors, it is most likely affected by cork taint.

- The presence of cork taint in individual wineries' wines varies greatly. However, monitoring haloanisoles in wines is vital as an integral component of product quality control techniques before the wine's presentation to the market.

3. Reduction Faults: Wine reduction is the polar opposite of oxidation in wine.

- The deprivation of oxygen in the winemaking process means that the wine cannot polymerize since there is insufficient oxygen for the molecular process to occur.

- The typical reduction aroma in wine is caused by a chemical known as hydrogen sulfide.

- A severely reduced wine will have an overpowering sulfurous odor, typically reeking eggs, matches, or other delectable swap notes. This is a smell that usually develops in the winery. It can occur during primary fermentation or later while the wine is in storage.

[[relatedPurchasesItems-41]]

- Elemental sulfur, often known as sulfur dust or wettable sulfur, is a typical material used in the vineyard to combat mildew and mold.

- If the sulfur is administered too close to harvest by chance, the grapes will still have sulfur when plucked and taken to the winery. And if that gets into the juice or the fermenter, yeast will go ahead and convert that elemental sulfur to H2S, and the tank will smell like rotten eggs.

- In some cases, strong swirling or decanting might aid in the removal of these "reductive" flavors from the wine.

4. Refermentation/ Secondary Fermentation: Refermentation causes bubbling in wine. It is particularly common in young bottles of red wine. You may also hear a sound akin to opening a bottle of Soda as you open the wine.

- Re-fermentation occurs when residual sugar is bottled with the wine, resulting in bubbles. It is prevalent in low-intervention winemaking, where no sulfites are applied.

- It is more common in natural wines since they do not include sulfites, which help to stabilize the wine.

- Some winemakers perform secondary fermentation to add a little zip to their wines, mainly sparkling wines.

5. Sulfites and Sulphides: Wine contains sulfites as a preservative.

- Mercaptan (an organic compound with a distinct odor) is the most common manifestation of a sulfur-related defect. If you experience rotten egg, burnt rubber, cooked garlic, or skunk odors in your wine after decanting it for a while, you most likely have a mercaptan problem.

- Sulfur is used in small amounts to stabilize practically all wines. Sulfur compounds have a smokey odor, similar to a lit match or cooked cabbage.

- Most of these odors dissipate within 15–20 minutes of opening a bottle.

- The unpleasant flavor is reduced by decanting.

6. Volatile Acidity (Acetic Acid): Volatile acidity refers to the presence of distillable steam acids in wine, most notably acetic acid, but also lactic, formic, butyric, and propionic acids. Although acetic acid is commonly regarded as a spoiling product (vinegar), some winemakers desire a low or scarcely detectable quantity of acetic acid to increase the perceived complexity of a wine.

Image Source: Rodwine

- Vinegar taint is one of the most common wine flaws, and it is also a tool employed by some high-quality winemakers to generate complexity in their flavor profiles.

- Furthermore, the creation of acetic acid results in the simultaneous formation of additional, sometimes unpleasant, scent molecules (see ethyl acetate and acetaldehyde).

- Aside from the unpleasant odors, acetic acid and acetaldehyde are also toxic to Saccharomyces cerevisiae. It can also lead to stuck fermentations.

- An extremely acidic wine that typically smells like balsamic vinegar. Wine may also have a strong odor of nail polish remover.

7. Microbial Faults: Microbial faults are frequently the result of contamination with bacteria or yeasts that have not been suppressed sufficiently by sulfur dioxide (SO2), which is used in winemaking as an antibacterial and antioxidant agent.

- Brettanomyces bruxellensis, for example, is a notable species employed in the production of some types of Belgian ales. But, unfortunately, it is also the one responsible for wine deterioration.

- Lactic acid bacteria (LAB) are utilized during malolactic fermentation (MLF) to convert malic acid to lactic acid. As a result, it smells like a swampy, stale dishcloth or sauerkraut.

- The growth of Lactobacillus, Pediococcus, and even some Oenococcus species in wine, commonly after malolactic fermentation, creates various spoiling scenarios because they can produce unwanted aroma and flavor compounds.

By ensuring that the wine has adequate SO2 levels, maintaining a low pH (increased acidity) is more resistant to microbial activity. In addition, using clean grapes and disinfected winery equipment in a suitable environment can help prevent some of these wine faults. And can make your wine tasting experience free of these wine flaws or faults!

Article By Aakriti Rawat, Beverage Trade Network